When engineers talk about thermal management in high-performance electronics, the tungsten heat sink comes up as a solution that balances several competing demands at once. It’s not the cheapest option, nor is it the lightest or the easiest to manufacture. Yet it persists in applications where other materials have failed, and for good reason. Understanding why requires looking past simple thermal conductivity numbers and examining how materials behave over time, under stress, and in conditions that push conventional heat sinks beyond their limits.

Thermal Performance in Context

The first thing to understand about thermal performance is that raw conductivity tells only part of the story. Copper conducts heat better than tungsten on paper, moving thermal energy at roughly 400 watts per metre-kelvin compared to tungsten’s 173. Aluminium, the workhorse of consumer electronics cooling, clocks in at about 205. If conductivity were the only metric that mattered, tungsten wouldn’t merit consideration.

But thermal management in real-world applications involves more than simply moving heat from one place to another. It requires managing thermal gradients, absorbing heat spikes, and maintaining stable temperatures across components with different thermal properties. Tungsten heat dissipation excels in these more nuanced scenarios because of the material’s density and thermal mass.

At 19.3 grammes per cubic centimetre, tungsten packs enormous heat capacity into small volumes. When power loads fluctuate, as they do in pulsed laser systems, RF amplifiers, and switching power supplies, this thermal mass acts as a buffer. The material absorbs sudden heat spikes without dramatic temperature swings, then releases that energy more gradually. This damping effect protects sensitive components from thermal shock that can cause premature failure.

The Expansion Coefficient Advantage

Perhaps tungsten’s most significant benefit lies in its coefficient of thermal expansion. Materials expand when heated, and when different materials are bonded together, they expand at different rates. Over thousands of heating and cooling cycles, these mismatched expansions create mechanical stresses at the interfaces between materials.

Tungsten thermal solutions address this problem directly. The material expands at 4.5 parts per million per degree Celsius, closely matching semiconductor materials like gallium arsenide at 5.7 and silicon carbide at 4.0. Compare this to copper at 16.5 or aluminium at 23, and the benefit becomes clear. When a tungsten heat sink is bonded to a semiconductor device, thermal cycling doesn’t create the destructive stresses that occur with more conventional heat sink materials.

Singapore’s tungsten heat sink manufacturing sector has built expertise around exploiting this property, producing components for industries where thermal cycling failure isn’t acceptable:

- Medical laser systems that operate for years with minimal maintenance

- Telecommunications infrastructure running continuously through daily temperature variations

- Automotive electronics enduring extreme temperature swings from cold starts to sustained high-power operation

- Industrial laser cutting equipment cycling on and off throughout production shifts

- Aerospace electronics facing thermal extremes without possibility of field repair

Durability Through Material Properties

Durability in thermal management components means different things depending on the application. For consumer electronics, it might mean lasting three to five years of moderate use. For industrial equipment, it means decades of continuous operation under demanding conditions. Tungsten heat sinks serve the latter category.

The material’s melting point of 3,422 degrees Celsius provides an enormous safety margin. Even in extreme applications, operating temperatures remain thousands of degrees below the point where material properties begin to degrade. This thermal stability means performance doesn’t drift over time as it can with materials operating closer to their limits.

Mechanical properties contribute to longevity as well. Tungsten resists deformation under load and maintains structural integrity across wide temperature ranges. Unlike aluminium, which softens noticeably at elevated temperatures, or copper, which can creep under sustained thermal stress, tungsten thermal management components maintain their shape and dimensional accuracy throughout their service life.

Corrosion resistance adds another layer of durability. Tungsten forms a protective oxide layer that prevents further oxidation in most environments. This stability matters in applications exposed to humidity, temperature cycling, or corrosive atmospheres where other metals might degrade.

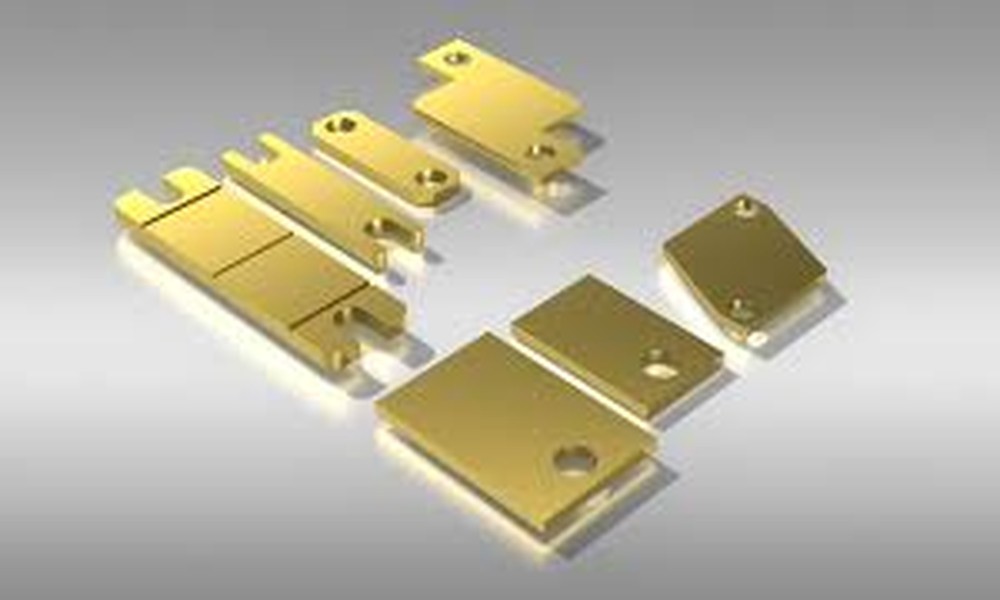

Composite Solutions

Pure tungsten isn’t always the answer, and this recognition has driven development of copper-tungsten composites that combine strengths of both materials. These composites typically contain 10 to 30 per cent copper infiltrated into a porous tungsten matrix. The copper improves thermal conductivity whilst tungsten maintains the low coefficient of thermal expansion and structural stability.

Singapore’s tungsten heat sink industry produces these composite materials using powder metallurgy and infiltration techniques. The process creates materials with customised properties:

- Thermal conductivity between pure tungsten and pure copper

- Expansion coefficients tuned to match specific semiconductor materials

- Density and cost balanced for the application requirements

- Machinability improved compared to pure tungsten

Economic Considerations

The benefits come at a cost. Tungsten costs more per kilogramme than aluminium or copper, and machining it requires specialised tooling and expertise. These factors limit tungsten heat sink applications to situations where the performance benefits justify the expense. That calculation increasingly favours tungsten as electronics become more powerful, more compact, and more expensive to replace when thermal management fails.

Making the Decision

No single material suits every thermal management challenge. But when applications demand long service life, stable performance across wide temperature ranges, tolerance for thermal cycling, and compact thermal solutions that won’t fail due to thermal expansion mismatch, the benefits of a tungsten heat sink outweigh its costs and manufacturing challenges.

Leave a Reply