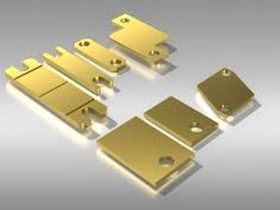

When it comes to ensuring the durability and functionality of fasteners in various applications, one of the most important factors to consider is the coating or finish applied to them. Whether it’s for corrosion resistance, aesthetics, or improving wear resistance, the choice of coating or finish can significantly impact a fastener’s overall performance, longevity, and cost-effectiveness.

In this post, we’ll explore how different coatings and finishes can influence the performance of fasteners and why they are essential in various industrial and construction applications.

- Understanding Fastener Coatings and Finishes

Before diving into the impact on performance, it’s important to understand what we mean by coatings and finishes in the context of fasteners:

- Coating: A layer of material applied to the surface of the fastener to protect it from corrosion, wear, or other environmental factors. Coatings are typically applied using methods like electroplating, hot-dipping, or spraying.

- Finish: Refers to the final surface texture and appearance of a fastener. Finishes can be functional, like improving grip or minimizing friction, or decorative for aesthetic purposes.

Both coatings and finishes can play a critical role in the fastener’s performance, corrosion resistance, and ability to handle various mechanical stresses.

- How Coatings and Finishes Impact Fastener Performance

Corrosion Resistance

One of the most significant factors that coatings and finishes address is corrosion resistance. In environments exposed to moisture, chemicals, or salt (such as marine or outdoor construction), corrosion can severely reduce the lifespan of a fastener.

- Zinc Coating (Galvanization): One of the most common coatings, galvanization involves coating fasteners with a layer of zinc. This provides a protective barrier that prevents rust and corrosion. It’s ideal for applications where fasteners are exposed to moisture or harsh weather.

- Chromate Conversion Coating: Often used for fasteners made of aluminum, this coating helps protect the metal from corrosion while still maintaining its appearance.

- Stainless Steel: While not technically a coating, stainless steel fasteners are naturally resistant to rust due to their composition. However, for extreme conditions, additional coatings like passivation can be used to enhance their performance further.

Wear Resistance

Fasteners in high-stress applications—such as automotive, aerospace, and heavy machinery—are exposed to significant wear and tear. Hard coatings and special finishes can dramatically improve the wear resistance of fasteners, helping them withstand friction and stress over time.

- Nickel Plating: This finish provides both corrosion resistance and abrasion resistance, making it an excellent choice for fasteners in automotive engines or machinery exposed to constant movement and pressure.

- Phosphate Coating: This is often used to improve the wear resistance of fasteners by creating a porous surface that can hold lubricants. It’s commonly used in automotive and military applications.

Friction Reduction and Lubrication

Certain finishes are specifically designed to reduce friction and wear between fasteners and other parts they interact with. This is particularly important in applications where fasteners need to be tightened frequently or reused.

- Black Oxide Coating: This is a rust-resistant finish that also offers some level of friction reduction, making it ideal for fasteners that are tightened frequently, such as in machinery.

- Dry Lubricant Coatings: Coatings like PTFE (Polytetrafluoroethylene) or molybdenum disulfide are applied to reduce friction between fasteners and other components. These coatings are particularly useful in environments where fasteners need to be reused or disassembled.

Aesthetic Appeal

While function is the primary concern, appearance can also be important for certain applications, especially when fasteners are visible to the public or are part of a finished product.

- Anodizing: Often used for aluminum fasteners, anodizing creates a durable finish that can also be dyed for aesthetic purposes. It’s often used in consumer electronics or high-end machinery where appearance matters.

- Bright Zinc Plating: For decorative fasteners, bright zinc plating provides a shiny, clean finish that is both visually appealing and protective against rust.

- Choosing the Right Coating or Finish for Your Application

Selecting the appropriate coating or finish depends on several factors:

- Environmental Conditions: For harsh outdoor conditions, galvanization or stainless steel might be the best choice, while for more controlled environments, nickel plating or anodizing could suffice.

- Mechanical Stress: If the fasteners are subjected to high wear and friction, coatings like nickel plating or dry lubricants are ideal for minimizing wear.

- Aesthetic Requirements: For applications where appearance matters, bright zinc plating or anodizing are great choices to combine protection with visual appeal.

- Cost Considerations: Some coatings and finishes may come at a higher cost due to the complexity of the process. It’s essential to balance the performance needs with your project’s budget.

- Conclusion

Coatings and finishes are far more than just a cosmetic feature on fasteners—they are crucial to their performance and longevity. From corrosion resistance to wear protection and friction reduction, the right coating or finish can drastically enhance the fastener’s performance, especially in demanding environments.

When choosing a coating or finish for your fasteners, consider factors such as environmental exposure, mechanical stress, aesthetic needs, and cost. Selecting the right treatment ensures that the fasteners will function optimally and last for the life of the project.

If you need guidance on selecting the best coating or finish for your fasteners, our experts are here to help. Get in touch with us today for tailored solutions and recommendations!